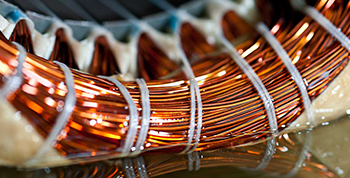

For the dip-roll process the parts have to be preheated to temperatures of 80-130°C in order to achieve quickly the gelling and curing temperatures. The resin is stored into in a small dipping tank and preferably stators are applied by rotating into the dipping tank. In order to avoid any dropping losses preheating temperatures, rotation speed and dipping depth have to be well adjusted. The resin immediately adopts the temperature of the winding, becomes considerably more thin fluid and is distributed uniformly throughout the winding as a result of rotation and capillary force. Curing occurs by circulating air. It recommended to keep the rotation running the first curing period.